The Type1 Light controllers are 2nd generation V2000 CPU modules. The Unified Controller nv series™ Type1 Light controllers are available in a range of options for a variety of industrial and process control applications.

Overview

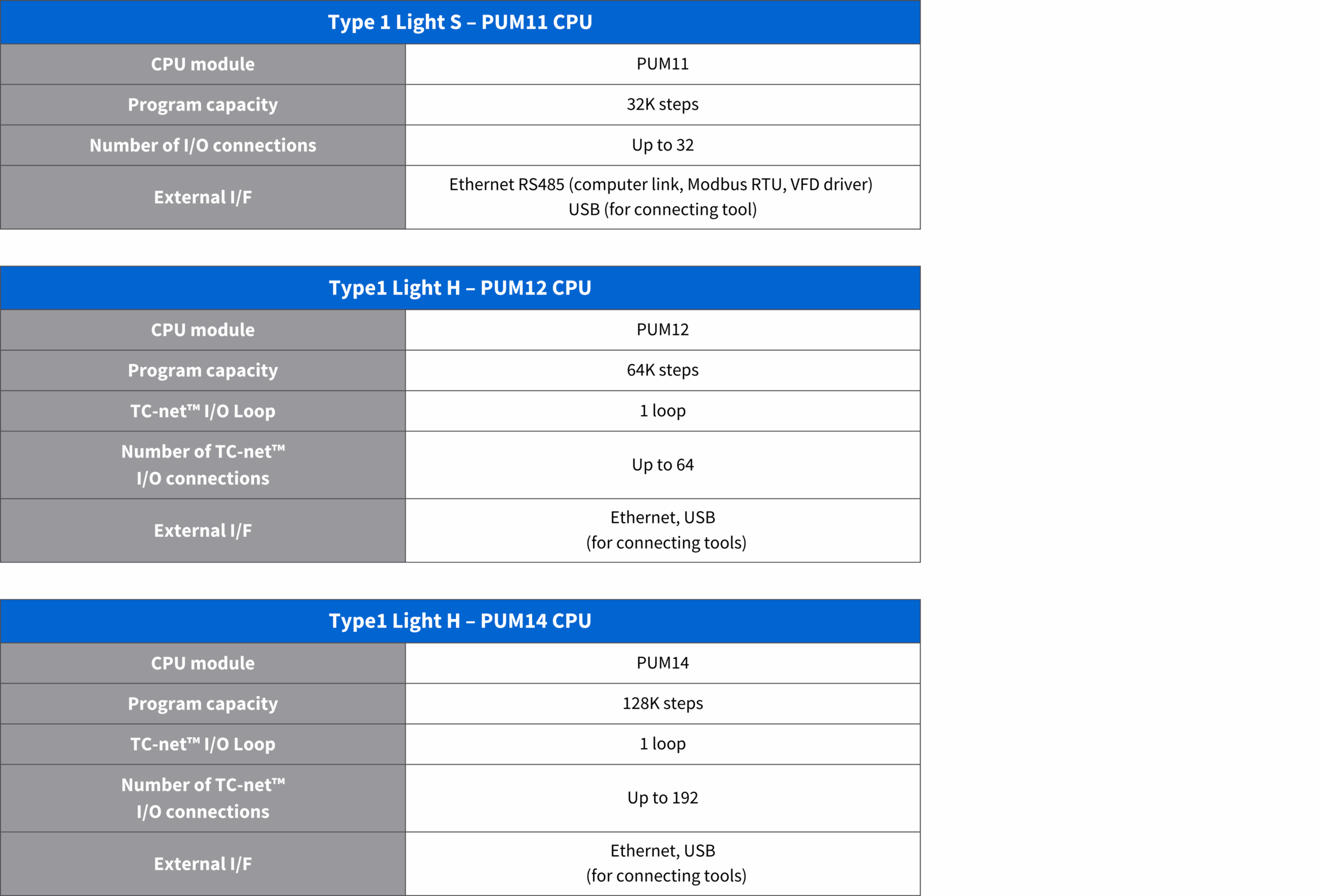

Specifications

Download Center

Training

Overview

Type 1 Light S – PUM11 CPU

Standard Sequence Control Module

The Type1 Light S CPU mounts in a standard V2000 I/O rack (3 I/O, 5 I/O or 8 I/O racks are available). It can replace a S2E module. The Type1 Light S does not support racks with station bus, or I/O modules that require a station bus.

Built-in Communication Options

The Type1 Light S CPU has both an RS485 port and an Ethernet port, which supports Toshiba’s ASCII computer link protocol. This allows connection by any HMI or SCADA software that has the Toshiba computer link driver. Also, Modbus® TCP/IP, Modbus® RTU, and direct communication with Toshiba LV VFDs.

Type1 Light H – PUM12 CPU

High-performance Sequence Control Module

The Unified Controller nv series™ TC-net™ I/O is built-in to the Type1 Light H CPU. It can be applied to I/O systems to provide enhanced performance. The master station, built into the CPU module, enables direct connection of the TC-net™ I/O loop. A 4 km-long remote I/O system than can be installed at low cost. The connected I/O can be selected from Integrated Controller V2000 series I/O (G2 I/O) or Unified Controller nv series™ TC-net™ I/O.

Remote I/O Configuration

The system collects and controls remote signals in real-time. The TC-net™ I/O is a high-speed, robust I/O system for optical cable communication with strong electrical noise resistance.

Type1 Light D – PUM14 CPU

Redundant Sequence Control Module

The Type1 Light D CPU supports redundancy. Redundancy enables greater productivity by providing the highest system availability. With a program capacity of 128K steps and the ability to connect up to 192 I/O modules, the Type1 Light D is ideal for critical medium and large-scale systems. The module can also be used in a single module configuration.

High Performance and Critical System Reliability

Automatic switching to the secondary CPU occurs if a problem is detected in the primary CPU.

Insulated Bearings

Extended Horsepower Capability

Insulation with Wide Thermal Capability

Low Vibration

Specifications

Lorem ipsum is placeholder text commonly used in the graphic

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

Download Center

Catalog

DATA PACKAGES

Brochures

Manuals

technical References

Drawing

SOftware

Catalog

I am tab 1 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

DATA PACKAGES

Brochures

Manuals

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

technical References

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Drawing

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

SOftware

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Training

[related_post_acf]