The Toshiba EQP Global® 661 motor is specifically designed for constant speed or inverter duty air-to-air heat exchanger applications found in petrochemical and chemical processing environments. This totally enclosed fan cooled motor meets API 661 specification and offers a 50,000-hour bearing life for belted applications. Built to meet or exceed IEEE® Std. 841-2021 requirements, it also features an IP56-rated enclosure and a corrosion-resistant severe duty epoxy paint system, allowing it to withstand demanding operating conditions, including 100% humidity.

- Products

- Low Voltage General Purpose

- Motors

- EQP Global® 661

Search by Rating

Overview

Specifications

Download Center

Training

Overview

Application Specific Design

Suitable for horizontal and vertical mounting, the 661 motor features IP56 protection and corrosion-resistant epoxy paint finish, which enhance durability in Class I, Div 2 A-D environments.

Vertical Lifting Provisions

This feature allows for ease of installation in both vertical shaft-up and vertical shaft-down mounting applications.

Shaft Strength

High-strength 4140 shaft steel offers exceptional toughness, and wear resistance, making it ideal for heavy-duty applications.

Ingress Protection

Labyrinth seals on both the DE and NDE of the shaft combined with an umbrella rain slinger on the DE and gasket sealant between the frame and bearing brackets provide IP56 protection, which delivers reliable defense against 100% humidity.

Multi Drain Provisions

Multiple drain provisions on the brackets, frame, and conduit box provide effective drainage in all vertical and horizontal mounting positions.

Inverter Duty Rated

Designed for use with an adjustable speed drive for energy savings at optimum fan speed, the EQP Global 661 motor features an insulation system that meets NEMA MG1 Part 31 standards and is engineered to withstand sharp voltage spikes up to 2000 V in 0.1 μs. It also offers versatile speed ranges of up to 60:1 Variable Torque and 10:1 Constant Torque.

Insulated Bearings

Extended Horsepower Capability

Insulation with Wide Thermal Capability

Low Vibration

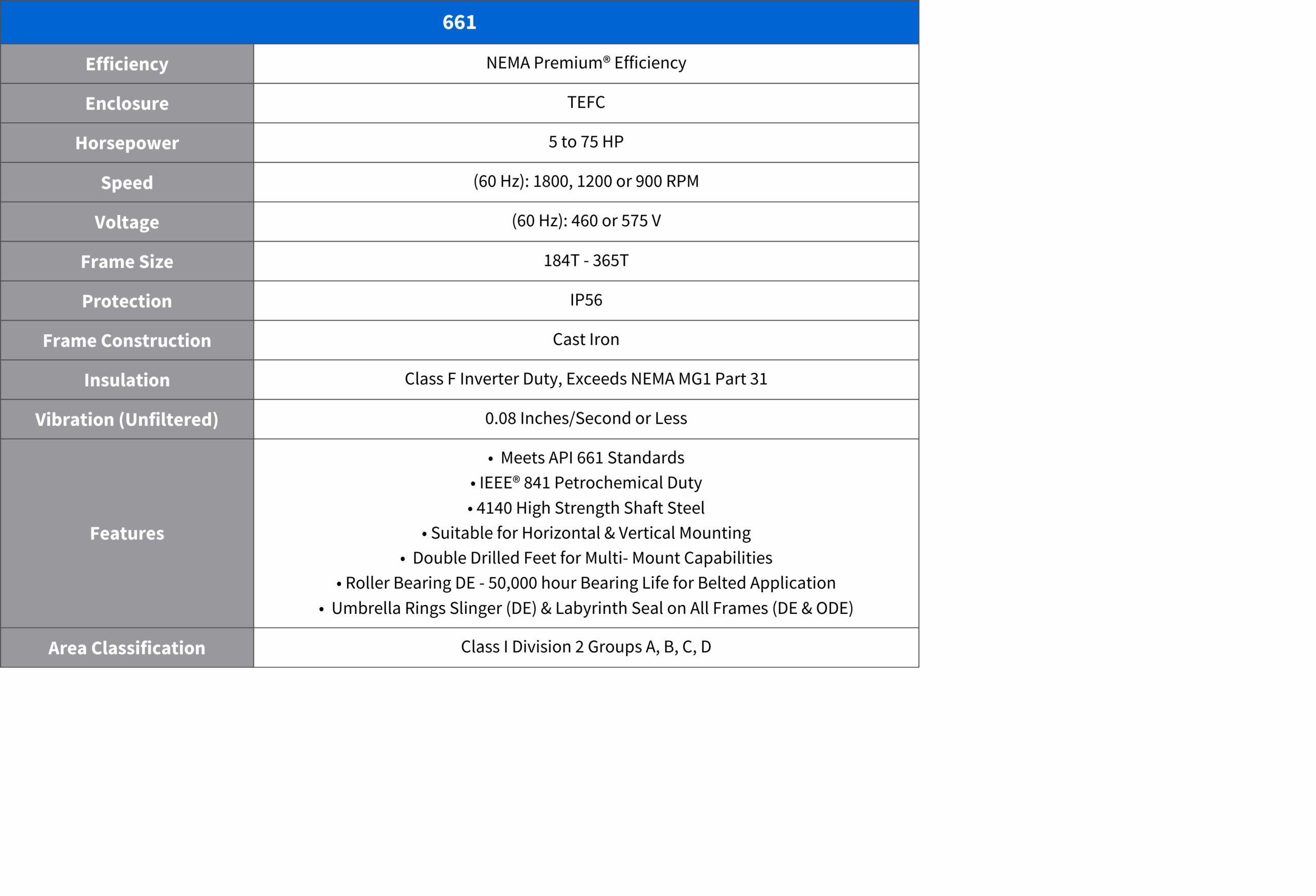

Specifications

Lorem ipsum is placeholder text commonly used in the graphic

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

Download Center

Catalog

DATA PACKAGES

Brochures

Manuals

technical References

Drawing

SOftware

Catalog

I am tab 1 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

DATA PACKAGES

Brochures

Manuals

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

technical References

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Drawing

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

SOftware

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.