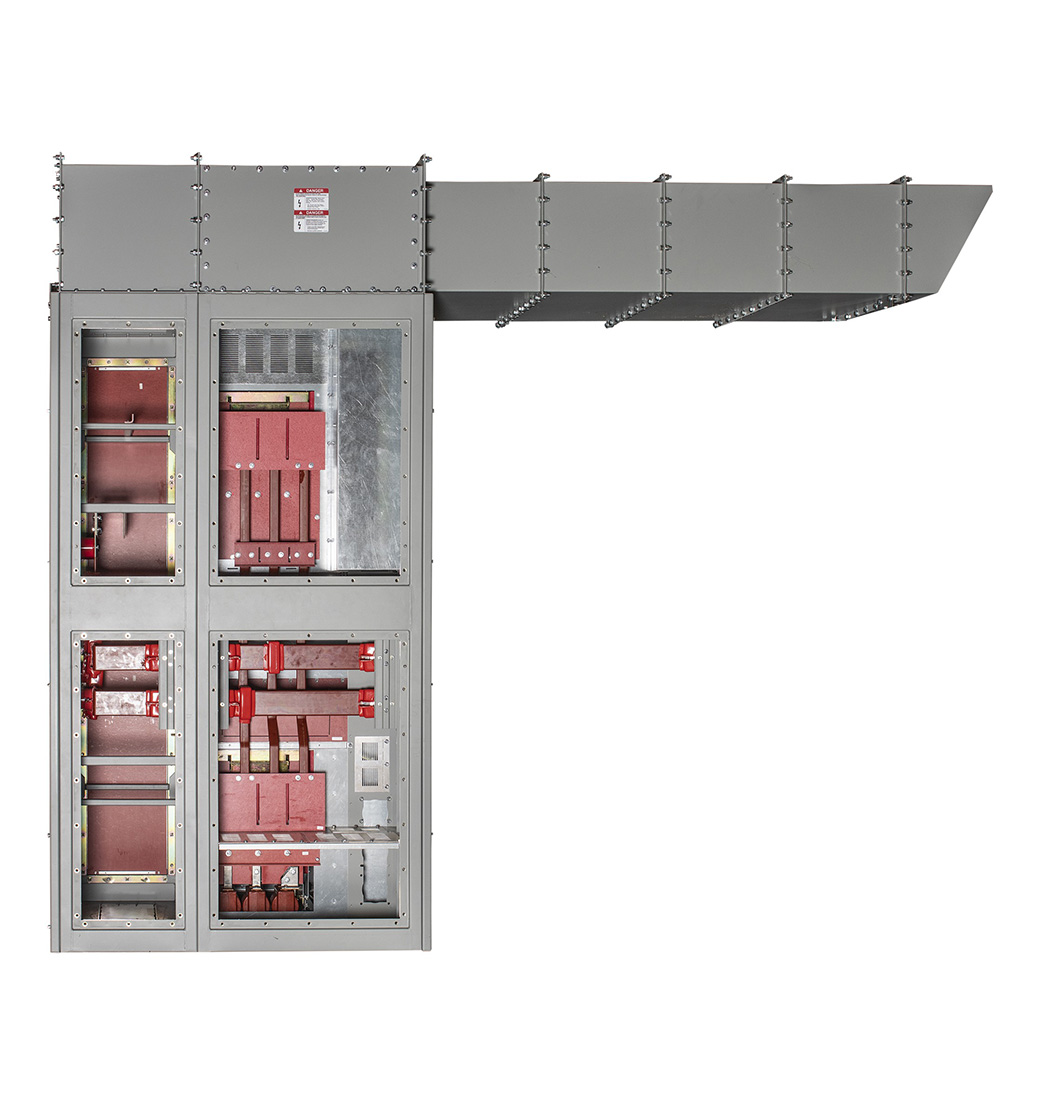

The Arc-Resistant JK (AR-JK) Motor Control Center is designed to increase safety, reliability, and uptime. Arc faults result from electric current traveling through the air between conducting metals due to factors like accidental contact, improper work procedures, or inadequate maintenance. These faults release dangerous energy levels, causing extreme heat, light, noise, and toxic fumes, which can lead to serious injuries, unplanned downtime, and costly replacements. Utilizing advanced technology, high-quality materials, and structural design, the AR-JK effectively mitigates the risks and costs associated with an arc fault by containing and diverting arc-related explosions.

- Products

- Controls

- Medium Voltage MCC

- Arc-Resistant JK

Overview

Specifications

Download Center

Training

Overview

Type 2B Accessibility

Offers increased protection around the entire perimeter of the AR-JK, including instances when the low voltage compartment is open and under maintenance.

Insulated Main Bus

Insulated main bus prevents inadvertent contact with bus bars and isolates them to limit the spread of an arc blast.

Modular, Pre-Assembled Exhaust Plenum

Exhaust plenum channels fire, smoke, and debris from an arc fault out and away from personnel around the perimeter of the AR-JK MCC. The modular design enables the plenum to be installed facing the left, right or back depending on user requirements.

Advanced Pressure Relief System

Designed to redirect arc blasts safely, an internal venting system and ventilation flaps are utilized to manage internal pressure.

Reinforced Structural Design

Reinforced doors, sides and end covers increase the AR-JK’s ability to safely withstand an arc fault explosion.

Bolted Pressure Isolation Switch

Designed with a mechanical interlock between the contactor and the isolation switch prevents opening or closing of the isolation switch unless the main contactor is opened.

Insulated Bearings

Extended Horsepower Capability

Insulation with Wide Thermal Capability

Low Vibration

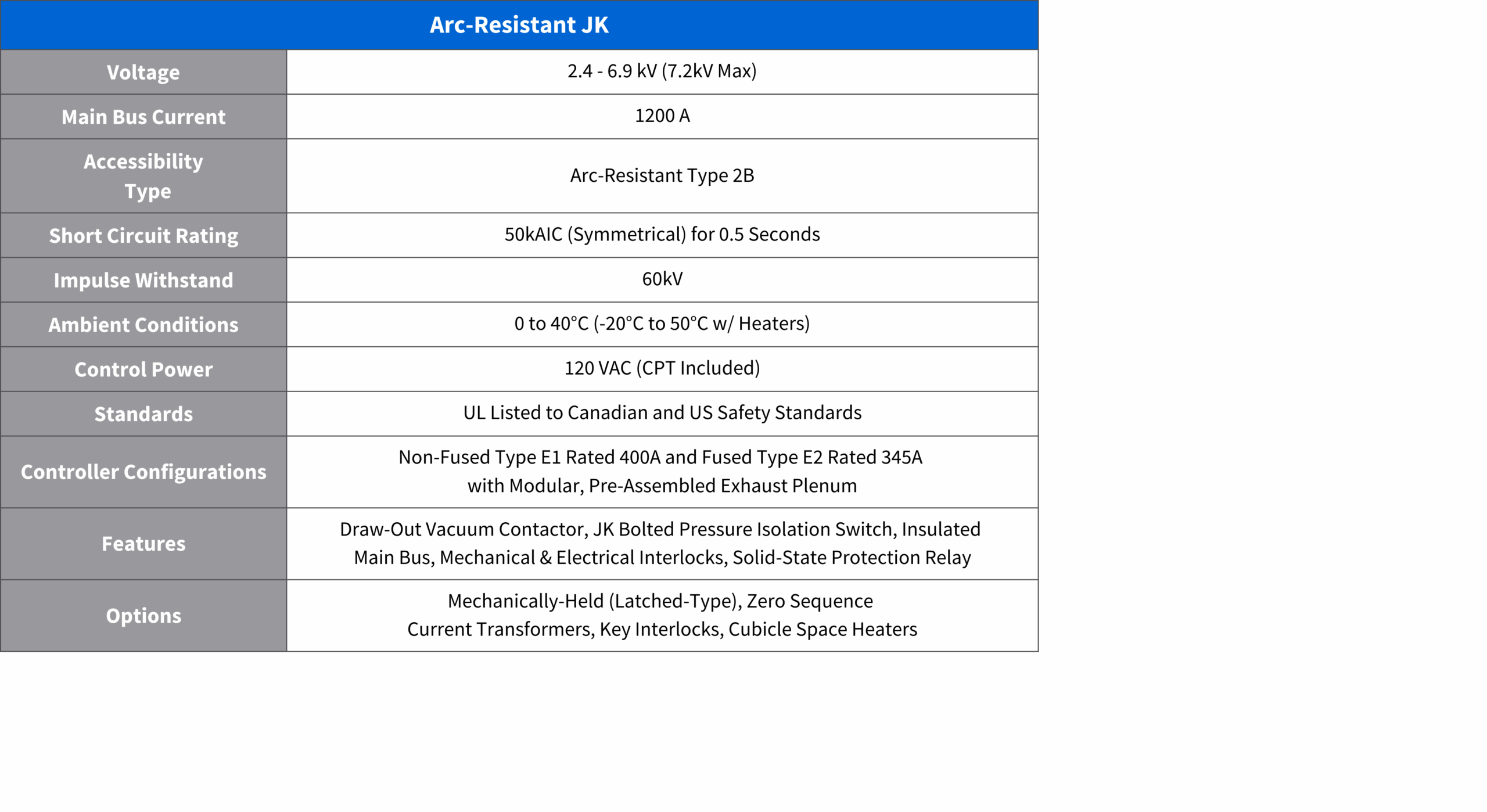

Specifications

Lorem ipsum is placeholder text commonly used in the graphic

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

- Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud.

Download Center

Catalog

DATA PACKAGES

Brochures

Manuals

technical References

Drawing

SOftware

Catalog

I am tab 1 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

DATA PACKAGES

Brochures

Manuals

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

technical References

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Drawing

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

SOftware

I am tab 3 content. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Training

[related_post_acf]